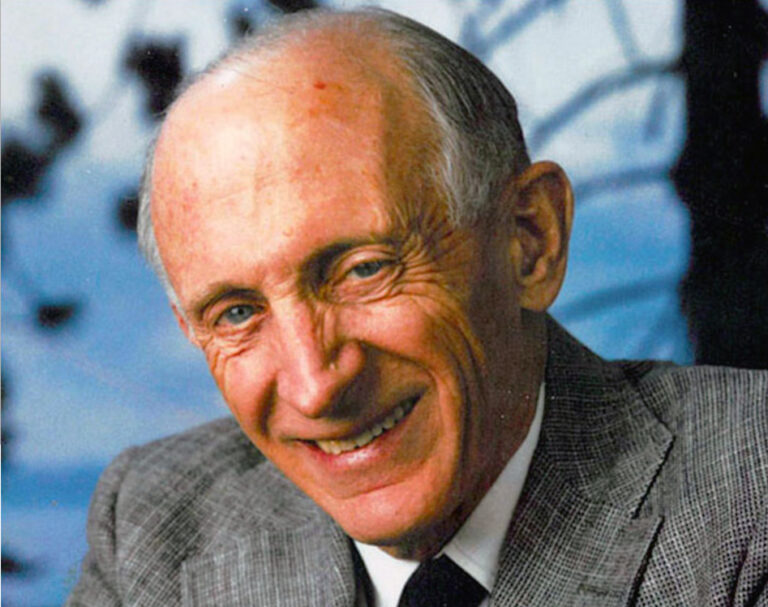

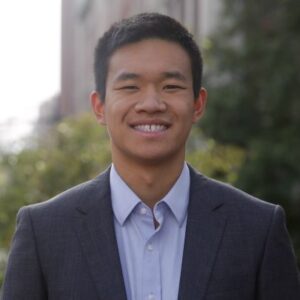

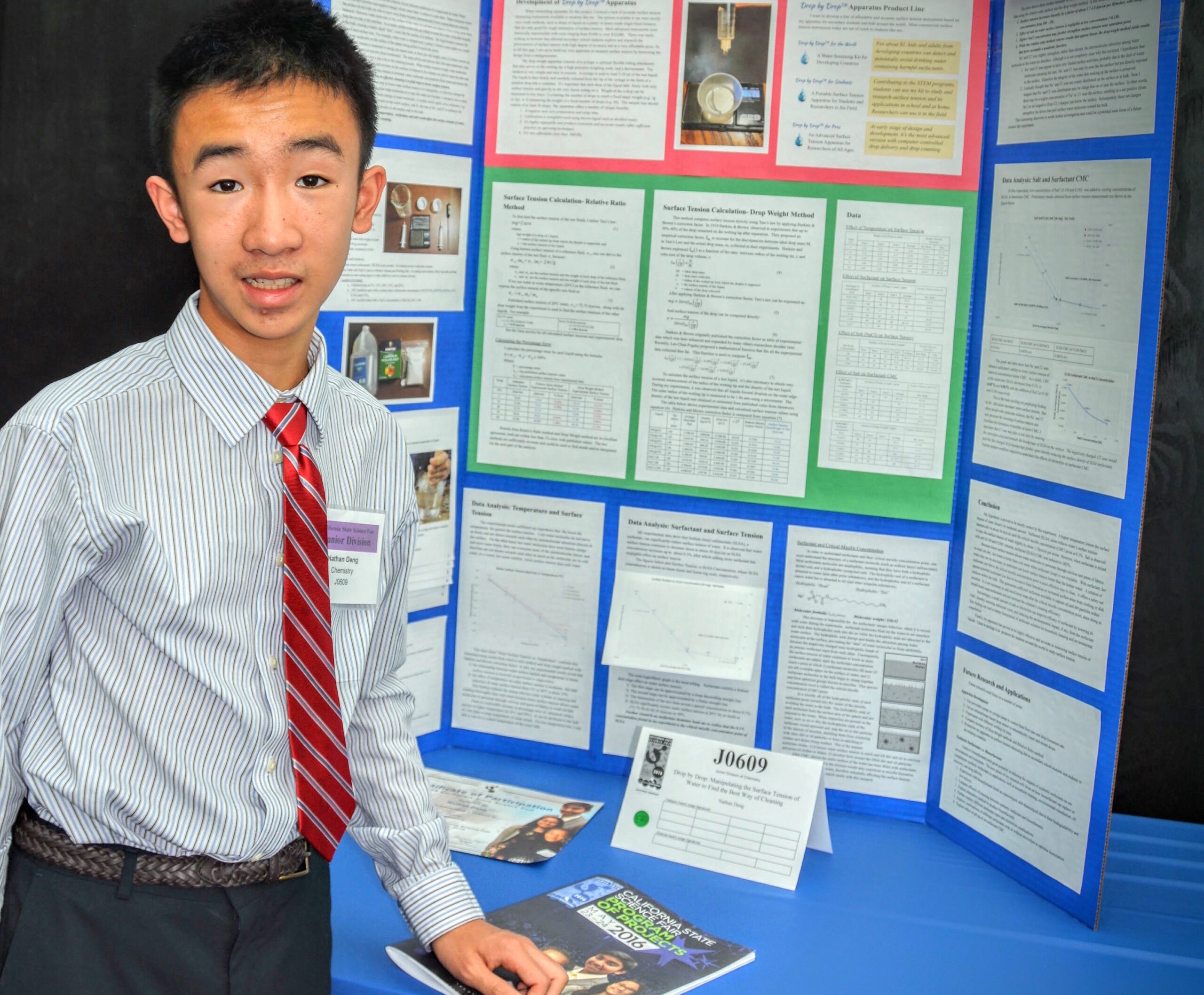

Nathan Deng, 2017 Broadcom MASTERS Lemelson Prize for Invention Winner

How many times have you stood at your sink, elbow deep in water scrubbing a pile of dirty dishes, and thought, “I wonder how soap works?” If you are like most people, you never have.

Meet Nathan Deng, a 14-year-old from San Marino, CA, who turned his curiosity about this tedious chore into an invention with the potential for real environmental impact. Deng’s interest in cleaning – a personal fascination for as long as he can remember – led him to research surface tension, and to invent his own apparatus for testing the surface tension of different liquids. Eventually, this testing apparatus helped him move closer to his goal of developing more effective, and environmentally safe cleaning methods – including a process for cleaning up oil spills.

Deng, a ninth grader, recently won a $7,500 Lemelson Award for Invention. Given annually to student inventors seeking to solve real-world problems, the award is part of the Broadcom MASTERS competition supported by Broadcom Foundation and the Society for Science & the Public. The competition is designed to encourage middle and high school students to pursue science and math. The aim is to inspire students to make college and career choices that enable them to become the next generation of engineers, scientists and innovators.

The Lemelson Foundation caught up with Deng in late December 2016 to learn what motivates him as a student inventor.

The Lemelson Foundation: So what started your fascination with cleaning?

Nathan Deng: I’ve always been curious about cleaning. I’m fascinated by how it works. I want to know the process or the underlying mechanism — like when I’m washing dishes at home, how does the soap work? And why hot water?

Inventing is not reserved for a select few geniuses; anyone, even a kid, has the innate ability to invent… Don’t be afraid, and keep trying. Find solutions to everyday problems, at home or at school. Before you know it. you’re inventing.

And how did you connect washing dishes to oil spills?

Cleaning was more of a curiosity-based interest. But I became more fascinated when I did research on the BP oil spill in the Gulf of Mexico. The U.S. tried to clean it up with a chemical called Corexit, but this actually made the situation worse by making the ocean water more toxic to swim in and for aquatic life. I was wondering if there was a better way to do this, with something that was efficient and environmentally friendly. This curiosity led me to study more about cleaning.

Cleaning dishes and oil spills are related because of a process called sorption. There are two types – adsorption and absorption. Adsorption is when a substance adheres to the surface of something and creates a film; this effects the surface only. Absorption is when a substance is dissolved by a liquid or a solid, and fully absorbed into it. An example of adsorption in household cleaning is scrubbing dishes, because whenever you eat, things get stuck to the dish, but stay on the surface. Cleaning this is adsorption. This is related to the oil spill version of cleaning because the oil gets stuck to surfaces, like a rock, and you want to clean it off. Absorption includes things like cleaning clothes. The dirty substances get absorbed into the clothes. This applies to oil spills because some of the stuff gets absorbed into the rock. And this requires a little more effort to clean.

So you had an interest and you saw the oil spill. Where did you go from there?

After doing this research on cleaning, I made a goal of finding an efficient and environmentally friendly way to clean. But this was too broad, and I wasn’t really sure where to start.

Then, in a class last year, I stumbled across the definition of surface tension in a text book, and I wanted to know if that had anything to do with cleaning. So I did more research and found that lowering the surface tension of liquids, water specifically, makes it better at cleaning because it breaks up the drops and allows it to flow more easily over surfaces of dirty objects. This inspired me to start my project studying the surface tension of liquids to see if that could bring me closer to my overall goal.

How did you start this research?

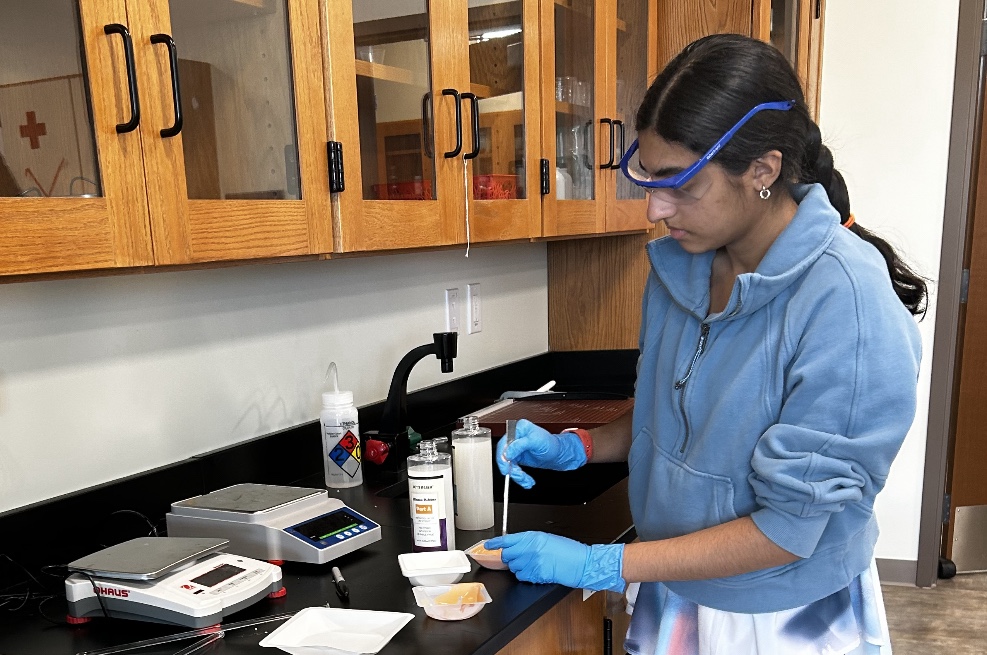

I started with a simple single beam balance that is commonly used in schools to measure surface tension, but it turned out that this was not sensitive enough to measure what I needed to know. There wasn’t an apparatus on the market that I could afford, so I invented my own from a syringe with tubing connected to the tip. It can measure surface tension using a principle called “drop weight.” I slowly press on the plunger of the syringe so that a drop forms at the tip, and keep pushing until the drop reaches a certain weight and drops into the container. How big a drop gets depends on the balance between surface tension and gravity. Whenever you suspend the drop, there is always gravity pulling on it. Surface tension keeps the drop held up until it reaches the maximum mass at which gravity overcomes that tension.

What did you learn through your research?

I had several different results. One conclusion was that increased temperature lowers the surface tension by moderate amounts. That’s why hot water is better for cleaning.

My second experiment was with surfactants – the main ingredient in soap. I found that adding more surfactant decreases the surface tension of water, but only to a point. Once that concentration point is reached, called the critical micelle concentration point, or CMC, the surface tension of the water stops lowering by a significant amount. The significance of this finding is that only lowering the surface tension of water does not affect water’s ability to interact with oil, so this won’t greatly improve cleaning. But the surfactant’s interaction with water produces an emulsifying agent called micelles. The micelles are able to capture the oil. The result is that surfactant not only lowers the surface tension of water, but you also get these micelles that actually emulsify or mix oil into the water. That’s something water cannot do on its own. By creating this emulsification effect, adding lots of surfactants to water can cause harm to the environment.

The most satisfying part about being an inventor is turning a curiosity, like mine with cleaning, into a testable idea. With repeated work and experimentation, you can turn it into a working product that can be used to help people improve their lives.

My third experiment is with salt. I found that salt increases the surface tension of water, making it a little worse for cleaning. My most important experiment was when I combined salt and surfactant with water. I found something very significant: When you mix these three things, it lowers the CMC so that you can use less surfactant in the water for the desired cleaning result, potentially saving the environmental impact of using more surfactant.

Why is preserving the environment so central to your studies and invention process?

I love to hike. I spend a lot of time hiking in my area, in places like the Angeles National Forest. I also have visited the Mohave Desert and would like to hike there. Caring about environmental sustainability comes from this love of hiking and observing nature. I wasn’t always so interested in science and technology, but the more I observed the natural world growing up, the more I wanted to learn how the underlying processes worked – and that meant chemistry.

I’m interested in green chemistry as a future career. From my research so far, I am inspired by the principles of green chemistry. It’s about efficiency and finding ways of being beneficial to the environment. This helped me define my goal and design my project.

Who helped and supported you in your research?

My father helped me with the more complex graphing and polynomial functions that are involved in using drop weight as a measure of surface tension. My teacher also helped by introducing me to the basic concepts of chemistry and lending me different materials that I needed to complete the research.

While my project was done completely at home, I am involved in STEM group projects in school that help me build problem-solving and science-related skills and knowledge. This makes me a better inventor.

What are you working on now?

After refining my drop weight measuring apparatus, I felt I wanted to contribute to the STEM community. So, I created three versions: One for students; one for developing countries; and one for researchers.

The first kit for students addresses the problem I faced when I wanted to do more research on surface tension. There weren’t any affordable, sensitive tools to measure the drop weight of liquids with low surface tension. I created the student kit so that other students like me could conduct new experiments.

The next kit is for people in developing countries. After doing research about surfactants, I found that there is a big issue of surfactant contamination around the world. Because of fewer regulations, industrial waste often is dumped directly into rivers. Surfactants are also not always filtered out by filtration systems. So, I created a kit to measure the surface tension of water sources as a means to test water quality. If people measure the surface tension and see it is very low, the water is probably contaminated by surfactants. This doesn’t guarantee that the water is clean, but it gives people an idea that their water is probably not safe.

My kit for researchers is what I’m working on now. It addresses the limitations of my original apparatus. I want to create a kit in which the plunger is motorized, using a peristaltic pump. This kit also includes a drop counter that uses an infrared beam below the tip of the tubing so that when a drop falls, the infrared beam breaks, and that is counted. This would allow for more experiments to be done and cut down on the tedium and margin for error.

I still face a lot of challenges to fully develop and market the kits. I am now exploring technologies that can help address the user education and support aspects of my invention. I think making sure that people understand how the apparatus works and are able to use it correctly is critical to its success.

What did you do when you got stuck or ran into problems in developing your invention?

At one point, I had a problem when measuring liquids with low surface tension, like soap. With such low surface tension, it was hard to squeeze out just one drop instead of a stream. What I did was attach a thin long tube to the end of the syringe. This solved the problem because it diminished the force on the liquid from the plunger, and I could hold the tubing as well for more stability. I came up with this solution by considering the blood draw needles and tubing that I saw at my mom’s hospital. I thought that if I could attach one of these tubes to the end, it would give me a buffer for the force of the plunger and I could control the drop a bit more.

What do you find most satisfying about being an inventor?

You know, when I started developing my apparatus, I wasn’t even thinking about being an inventor. I was just trying to create a solution for a problem I was facing. I couldn’t afford to buy the instrument (stalagmometer) that measures drop weight. I knew the principle of drop weight and, I knew that my idea of using a syringe should work the same way as a stalagmometer. So I made the prototype. And it worked well enough for me to complete my middle school science project.

But when I first tried to use my apparatus to find the critical micelle concentration (CMC) of surfactant solution, it failed to yield consistent data. I did some research and found that professional laboratories typically use a much more expensive precision equipment to find CMC. I thought to myself, “Am I wasting my time? My little apparatus would never have that kind of precision.”

Even my father – one of my biggest supporters – doubted that my apparatus was going to work (for surfactant). But he encouraged me to keep trying, “You can find the problem and keep trying to improve it,” he told me.

After many trials, errors, and refinements, I was able to determine the CMC using the syringe plus tubing and a few kitchen tools. I was excited, but still had doubts. “Can it be a coincidence?” “Is my procedure repeatable?” “Is my calculation correct?” I asked my father to run a few test trials to make sure it was repeatable by another person. To check, I used two different methods of calculating surface tension with my collected data, and when the results from the two methods were in agreement, I was finally satisfied.

That is the long way to say that the most satisfying part about being an inventor is turning a curiosity, like mine with cleaning, into a testable idea. With repeated work and experimentation, you can turn it into a working product that can be used to help people improve their lives.

What in your school experience has supported you in becoming an inventor? What could be better in supporting you and other kids in your class to become inventors?

In my 8th grade science class we were given a group project called “The Edible Car Project.” My partner and I had to build a car entirely out of edible parts (not even a metal nut was allowed!) that could successfully roll down a ramp in one piece. This project helped me to become an inventor. It involved a lot of engineering skills and thinking “outside the box,” which was unlike the common homework or test-based learning I was used to. I wish there were more open-ended challenges and projects in school so kids could experience first-hand the design and engineering process.

Do you have any advice for other kids who are interested in becoming inventors?

Inventing is not reserved for a select few geniuses; anyone, even a kid, has the innate ability to invent. Remember the time you built your own Lego design (of a car, a boat, or building), or found a clever way to fix a broken toy? You were engaging in the process of problem solving and inventing. Don’t be afraid, and keep trying. Find solutions to everyday problems, at home or at school. Before you know it, you’re inventing.

Also, for those kids who have started inventing, but are getting frustrated: Don’t expect results immediately. Start out with studying what you’re curious about and slowly progress toward a product. It’s going to take a lot of work to get to the final goal.

Nathan Deng isn’t the only inventor who’s been inspired by cleaning. The following innovations are more effective and eco-friendly ways to clean your kitchen, bathroom, office and beyond:

- Forpow Steribowl uses rechargeable UV light to kill germs, mold, bacteria, and allergens in your toilet.

- LG Hub Robot can take over your household chores such as cleaning your carpets, picking up trash, and even mowing your lawn!

- Circo Independent Dishwasher is a small manual dishwasher that spares you the frustration of individually washing dishes by hand, and it helps the environment.

- Cyber Clean Home & Office is a gel that helps to clean and disinfect those hard to reach-surfaces on your tech products.

- Aqua Fresco is an eco-friendly laundry process saves you money by recycling clean water and detergent for up to six months of loads!

- Whirlpool now offers a ventless clothing dryer that saves money and energy using an efficient heat pump and refrigeration system. The same air can be recycled load after load.